Lapidary: The Art of Gem Cutting

1- Rough

Selecting rough Amethyst for cutting requires a keen eye and a thorough understanding of the gem’s inherent qualities. When choosing rough Amethyst, look for pieces with vibrant and uniform coloration, preferably free from any visible cracks or fractures that might compromise the structural integrity of the final gem. Opt for specimens that exhibit a good degree of transparency and clarity, as these characteristics can enhance the gem’s brilliance once it’s cut and polished. Assess the rough Amethyst’s crystal structure, prioritizing pieces with well-defined and symmetrical shapes, as these tend to yield the most desirable results during the cutting process. Additionally, consider the size and shape of the rough Amethyst, ensuring it aligns with the desired cut and design, allowing for the creation of a stunning finished gem that fully embodies the inherent beauty of the Amethyst.

2- Preform

Preforming Amethyst is an essential and intricate process that forms the backbone of the lapidary art. At our lapidary workshop, our skilled artisans meticulously examine each piece of rough Amethyst, evaluating its unique characteristics and potential. With a delicate balance of precision and expertise, we delicately trim and shape the rough Amethyst, laying the foundation for the subsequent cutting and polishing stages. Our craftsmen utilize advanced tools and techniques to refine the rough Amethyst, ensuring the removal of any imperfections and creating a preliminary shape that aligns with the desired design. By emphasizing the significance of preforming, we prioritize the preservation of the Amethyst’s natural allure, allowing its inherent beauty to shine through in the final polished gem.

3- Shape & Size

Determining the shape and size of Amethyst is a meticulous and artful process that underscores our commitment to precision and craftsmanship at our renowned lapidary workshop. By carefully assessing the unique characteristics of each Amethyst, our skilled artisans employ a blend of expertise and creativity to select the most suitable shape and size that will best highlight the gem’s inherent beauty. Taking into account the natural patterns, color variations, and crystal structure, we strive to enhance the Amethyst’s visual appeal and create a harmonious balance between its form and function. Our meticulous approach ensures that each Amethyst is tailored to meet the specific design requirements, enabling us to deliver bespoke and exquisite gemstones that resonate with timeless elegance and sophistication.

4- Precision Cutting

Precision cutting Amethyst is a delicate and exacting craft that demands a deep appreciation for the gem’s unique properties and a commitment to perfection. At the heart of our lapidary work, we take pride in our ability to bring out the best in Amethyst through meticulous cutting. Using specialized tools and expertise, our skilled artisans carefully shape and facet each Amethyst with an acute focus on angles and measurements. The result is a gem that not only showcases the stone’s innate brilliance but also highlights its stunning color variations. Precision cutting is the key to unlocking the true potential of Amethyst, revealing its mesmerizing beauty and making it a gem of choice for jewelry connoisseurs who value both craftsmanship and the inherent charm of this regal stone.

5- Polishing

Polishing Amethyst is a transformative process that adds the final touch of brilliance to this captivating gemstone. At our esteemed lapidary workshop, we employ a meticulous and multi-step polishing technique to enhance the natural luster and shine of the Amethyst. Our skilled artisans carefully inspect each piece, ensuring that any imperfections or blemishes are skillfully removed before the polishing process begins. With the use of specialized polishing wheels and compounds, we delicately buff and refine the surface of the Amethyst, gradually revealing its inherent depth of color and radiant clarity. The result is a flawlessly polished Amethyst that exudes a captivating sheen, enhancing its allure and making it a stunning centerpiece for exquisite jewelry pieces.

1- Rough

Selecting rough Aquamarine for cutting involves a meticulous evaluation of several key factors to ensure the creation of a stunning, high-quality gem. Begin by examining the color of the rough Aquamarine, aiming for a piece with a rich, even blue hue that reflects a sense of clarity and depth. Look for specimens with minimal inclusions or fractures that could impede the cutting process, as a clean and flawless piece will yield a more polished and brilliant final gem. Consider the crystal structure of the Aquamarine, favoring well-formed, symmetrical shapes that can be effectively translated into a captivating cut. Furthermore, assess the size and orientation of the rough Aquamarine, ensuring it aligns with the intended design and cut, allowing for the extraction of the most captivating facets and maximizing the gem’s inherent luminosity and allure.

2- Preform

Preforming Aquamarine is a crucial step in the lapidary process that sets the stage for crafting stunning gemstones from rough Aquamarine specimens. During this initial phase, lapidaries assess and prepare the raw Aquamarine by removing excess material and shaping it into a more manageable form before the actual cutting and polishing. Delicate cuts and grinding techniques are employed to create a rough outline that aligns with the intended design. This process helps to ensure that any potential inclusions or imperfections are minimized, and the Aquamarine’s natural color and clarity can be optimally revealed during subsequent cutting and polishing. Preforming Aquamarine is an art in itself, serving as a foundation for the creation of exquisite gemstones that capture the ethereal beauty of this captivating blue-green gem.

3- Shape & Size

Determining the ideal shape and size of Aquamarine is a meticulous process that demands a keen understanding of the gem’s inherent characteristics and the intended design. At our distinguished lapidary workshop, we carefully evaluate each Aquamarine specimen, considering its unique color, clarity, and crystal structure. Our skilled artisans utilize their expertise to select the most suitable shape and size that will best highlight the gem’s natural beauty and maximize its visual appeal. With a focus on preserving the Aquamarine’s distinct color variations and delicate transparency, we meticulously assess the gem’s dimensions, ensuring that the chosen shape and size align seamlessly with the envisioned design. By emphasizing the significance of precise determination, we strive to create bespoke Aquamarine gemstones that exude timeless elegance and sophistication, captivating the essence of this enchanting blue-green gem.

4- Precision Cutting

Precision cutting of Aquamarine is a meticulous craft that showcases the expertise and dedication we bring to our lapidary work. Aquamarine, known for its delicate blue-green hues, deserves the utmost care during the cutting process to accentuate its natural beauty. Our skilled artisans use specialized tools and advanced techniques to cut and facet each Aquamarine with a keen eye for angles, proportions, and measurements. By carefully shaping the gem, we unlock its full potential, enhancing its brilliance and transparency, while maintaining the distinct color and clarity for which Aquamarine is prized. Precision cutting is the key to transforming raw Aquamarine into a mesmerizing gemstone, making it a perfect choice for those who appreciate both fine craftsmanship and the serene charm of this exquisite gem.

5- Polishing

Polishing Aquamarine is a meticulous process that brings out the mesmerizing brilliance and luster of this enchanting gemstone. At our esteemed lapidary workshop, we employ specialized techniques and equipment to delicately refine the surface of the Aquamarine, enhancing its natural transparency and clarity. Our skilled artisans meticulously inspect each Aquamarine, ensuring that any imperfections or blemishes are carefully addressed before the polishing process begins. By using a series of fine abrasives and polishing compounds, we gently buff and smooth the surface of the Aquamarine, gradually revealing its exquisite color and captivating radiance. The result is a flawlessly polished Aquamarine that exudes a subtle yet dazzling glow, making it an exquisite choice for elegant jewelry pieces.

1- Rough

Selecting rough Prasiolite for cutting demands a discerning eye and a comprehensive understanding of the gem’s unique characteristics. When choosing rough Prasiolite, prioritize specimens with a rich, uniform green color that exhibits a vibrant and inviting hue. Look for pieces with high transparency and minimal inclusions, as these qualities are essential for achieving optimal brilliance and clarity in the final cut gem. Assess the crystal structure of the rough Prasiolite, favoring well-defined and symmetrical shapes that can be effectively transformed into a captivating cut. Additionally, consider the size and orientation of the rough Prasiolite, ensuring it aligns with the desired cut and design, allowing for the creation of a stunning finished gem that embodies the mesmerizing allure of Prasiolite’s unique green radiance.

2- Preform

Preforming Prasiolite is a vital step in our intricate lapidary process, dedicated to transforming raw Prasiolite into exquisite gemstones. At our distinguished workshop, each Prasiolite specimen is meticulously assessed, taking into account its unique color variations, clarity, and structural features. Utilizing state-of-the-art tools and expert techniques, we delicately shape and prepare the Prasiolite, ensuring the elimination of any surface imperfections or irregularities. This essential stage lays the groundwork for subsequent cutting and polishing, enabling us to reveal the Prasiolite’s full radiance and allure. By emphasizing the importance of this initial phase, we are committed to delivering Prasiolite gemstones that exude timeless elegance and unparalleled sophistication, capturing the natural splendor of this enchanting green gem in its finest form.

3- Shape & Size

Determining the ideal shape and size of Prasiolite is a meticulous process that underscores our commitment to precision and craftsmanship at our esteemed lapidary workshop. With a profound understanding of the gem’s unique characteristics, our skilled artisans carefully evaluate each Prasiolite specimen, taking into account its distinct color variations, transparency, and inherent features. By employing expert knowledge and advanced techniques, we select the most suitable shape and size that will best highlight the Prasiolite’s natural beauty and maximize its visual impact. Emphasizing the significance of precise determination, we ensure that each Prasiolite is tailored to meet specific design requirements, allowing its inherent elegance and allure to shine through in the final polished gemstone.

4- Precision Cutting

Precision cutting of Prasiolite is an artful process that defines the expertise and commitment we bring to our lapidary work. Prasiolite’s delicate green hue deserves meticulous care during the cutting process to reveal its natural beauty. Our skilled artisans employ specialized tools and techniques, paying close attention to angles, proportions, and measurements. By shaping the gemstone with precision, we unlock its full potential, enhancing its transparency, color, and brilliance while maintaining its unique character. Precision cutting is the key to transforming raw Prasiolite into a mesmerizing gemstone, making it an ideal choice for those who appreciate fine craftsmanship and the serene charm of this exquisite green gem.

5- Polishing

Polishing Prasiolite is the final, transformative touch in our lapidary process that enhances the captivating beauty of this serene green gem. At our reputable workshop, we employ advanced techniques and specialized equipment to delicately refine the surface of each Prasiolite, enhancing its natural luster and brilliance. Our skilled artisans carefully inspect each piece, ensuring any imperfections or blemishes are expertly removed before the polishing process begins. By employing a series of precise polishing steps, we gradually unveil the Prasiolite’s captivating transparency, delicate color variations, and smooth texture, creating a flawless and radiant finish. The result is a Prasiolite that radiates a serene, ethereal glow, making it a stunning centerpiece for exquisite jewelry

1- Rough

Selecting rough Citrine for cutting involves a thorough assessment of the gem’s key characteristics to ensure the creation of a stunning, high-quality gemstone. When choosing rough Citrine, look for specimens with a rich, golden-yellow to orange-brown color, as these hues are indicative of high-quality Citrine. Prioritize pieces with good transparency and minimal inclusions, as these qualities are essential for maximizing the gem’s brilliance once it’s cut and polished. Assess the crystal structure of the rough Citrine, favoring well-defined and symmetrical shapes that will facilitate the cutting process and result in a more visually appealing final gem. Consider the size and orientation of the rough Citrine, ensuring it aligns with the desired cut and design, allowing for the creation of a radiant finished gem that fully embodies the warmth and charm of Citrine’s vibrant color palette.

2- Preform

Preforming Citrine is a pivotal step in our lapidary process, dedicated to shaping and preparing raw Citrine specimens for the subsequent cutting and polishing stages. During this crucial phase, our skilled artisans meticulously examine each Citrine specimen, evaluating its unique characteristics, including color, clarity, and structural features. Using precision tools and techniques, we delicately trim and outline the rough Citrine, ensuring the removal of any surface imperfections or irregularities. This preforming process establishes the foundation for the gem’s ultimate transformation, allowing for the subsequent cutting and polishing stages to accentuate the Citrine’s inherent brilliance and radiance. By emphasizing the importance of this initial phase, we ensure the preservation of the natural beauty of Citrine, enabling it to shine with unparalleled elegance and allure in its final form.

3- Shape & Size

Determining the optimal shape and size of Citrine is a crucial aspect of our meticulous lapidary process, emblematic of our dedication to precision and craftsmanship. At our distinguished workshop, each Citrine specimen is carefully evaluated, taking into account its unique color variations, transparency, and innate characteristics. Leveraging expert knowledge and advanced techniques, we meticulously select the most suitable shape and size that will best accentuate the Citrine’s natural beauty and maximize its visual impact. By emphasizing the significance of precise determination, we ensure that each Citrine is tailored to meet specific design requirements, allowing its inherent elegance and allure to radiate through in the final polished gemstone.

4- Precision Cutting

Precision cutting of Citrine is a refined craft that epitomizes the expertise and commitment we bring to our lapidary work. Citrine’s warm, golden hues deserve meticulous care during the cutting process to reveal its natural beauty. Our skilled artisans employ specialized tools and advanced techniques, paying close attention to angles, proportions, and measurements. By shaping the gemstone with precision, we unlock its full potential, enhancing its transparency, color, and brilliance while preserving its distinct character. Precision cutting is the key to transforming raw Citrine into a resplendent gemstone, making it an ideal choice for those who appreciate fine craftsmanship and the radiant charm of this exquisite gem.

5- Polishing

Polishing Citrine is a meticulous and transformative process that reveals the radiant beauty of this golden gemstone. At our esteemed lapidary workshop, we employ advanced techniques and specialized equipment to delicately refine the surface of each Citrine, enhancing its natural brilliance and luster. Our skilled artisans meticulously inspect each piece, ensuring that any imperfections or blemishes are expertly removed before the polishing process begins. By meticulously polishing the Citrine, we gradually unveil its vibrant golden hues and stunning clarity, creating a smooth and reflective surface that radiates a warm and inviting glow. The final result is a dazzling and radiant Citrine gem that is sure to captivate the eye and elevate any piece of jewelry.

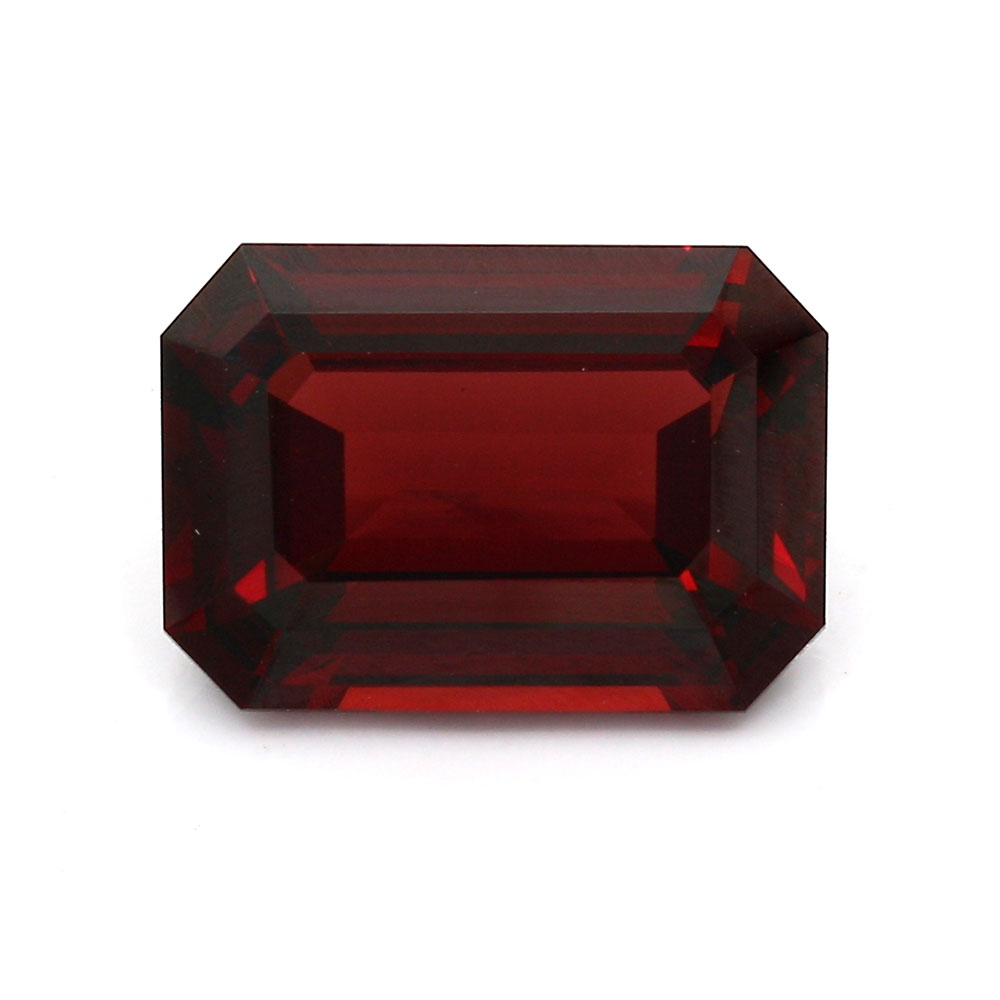

1- Rough

Selecting rough Almandine Garnet for cutting involves a thorough evaluation of the gem’s intrinsic qualities to ensure the creation of a magnificent finished stone. When choosing rough Almandine, prioritize specimens with a deep and rich red hue, as this is the hallmark of this particular Garnet variety. Look for pieces with high transparency and minimal inclusions, as these characteristics are essential for achieving optimal brilliance and clarity in the final cut gem. Assess the crystal structure of the rough Almandine, favoring well-formed and symmetrical shapes that will facilitate the cutting process and result in a more visually appealing final gem. Consider the size and orientation of the rough Almandine, ensuring it aligns with the desired cut and design, allowing for the creation of a striking finished gem that fully embodies the captivating allure of Almandine’s deep red color.

2- Preform

Preforming Almandine garnet is a crucial preliminary step in our lapidary process, dedicated to shaping and preparing raw Almandine specimens for the subsequent cutting and polishing stages. At our esteemed workshop, our skilled artisans carefully evaluate each Almandine specimen, considering its unique attributes, including color, clarity, and crystal structure. Leveraging expert knowledge and state-of-the-art tools, we delicately trim and outline the rough Almandine, ensuring the removal of any surface imperfections or irregularities. This essential preforming process serves as the foundation for the gem’s ultimate transformation, allowing for the subsequent cutting and polishing stages to accentuate the Almandine’s inherent brilliance and radiance. By emphasizing the importance of this initial phase, we ensure the preservation of the natural beauty of Almandine, enabling it to shine with unparalleled elegance and allure in its final form.

3- Shape & Size

Determining the ideal shape and size of Almandine garnet is a critical aspect of our meticulous lapidary process, demonstrating our commitment to precision and artistry. At our distinguished workshop, each Almandine specimen undergoes a thorough assessment, considering its unique color variations, transparency, and natural characteristics. Our skilled artisans utilize their expertise to select the most suitable shape and size that will best enhance the Almandine’s inherent beauty and maximize its visual impact. By emphasizing precise determination, we ensure that each Almandine is tailored to meet specific design requirements, allowing its intrinsic elegance and allure to shine through in the final polished gemstone.

4- Precision Cutting

Precision cutting of Almandine Garnet is a sophisticated process that requires a delicate balance of skill and expertise. At our renowned lapidary workshop, we meticulously evaluate each Almandine Garnet, taking into consideration its rich red color and natural inclusions. Our skilled craftsmen use specialized tools and techniques to precisely cut the gemstone, paying close attention to its unique facets and proportions. By emphasizing precise measurements and meticulous angles, we aim to enhance the Almandine Garnet’s brilliance and clarity, showcasing its inherent beauty in the most exquisite manner. Through our commitment to precision cutting, we strive to create Almandine Garnets that radiate a captivating and timeless allure, making them a cherished addition to any jewelry collection.

5- Polishing

Polishing Almandine Garnet is a precise and transformative process that unveils the captivating radiance of this deep red gemstone. In our dedicated lapidary workshop, we employ advanced techniques and specialized equipment to delicately refine each Almandine, accentuating its natural brilliance and luster. Our skilled artisans meticulously examine each piece, ensuring that any imperfections or blemishes are expertly eliminated before the polishing procedure commences. By carefully polishing the Almandine, we gradually reveal its rich color and remarkable transparency, creating a polished surface that emits a captivating, fiery glow. The end result is an Almandine Garnet that exudes an alluring and sophisticated charm, making it a stunning focal point for elegant jewelry.